Mobile CT scanners bring advanced imaging to a variety of healthcare environments—rural clinics, temporary overflow sites, or hospitals undergoing renovations—without the need for permanent construction. However, to leverage the benefits of mobility, certain compromises in design, performance, and workflow are inevitable. Below is a detailed look at how a mobile CT scanner’s specifications and environment can differ from those of a permanently installed system, and how these differences can impact imaging quality and operational efficiency.

Structural and Space Constraints

Gantry Size and Weight

Mobile Design vs. Fixed Suite

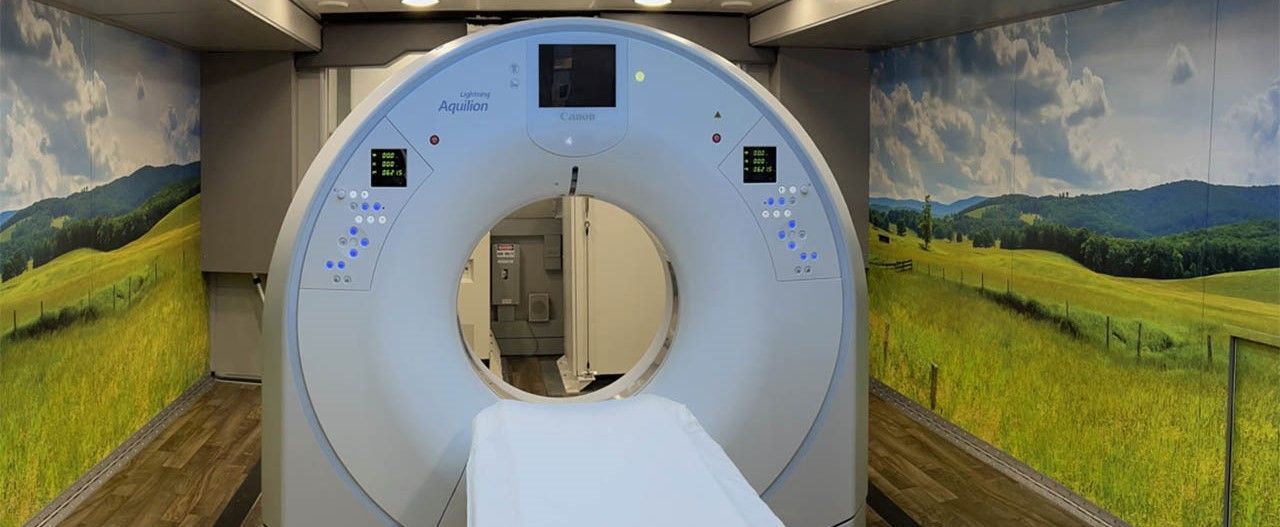

Mobile CT scanners are designed to fit within the dimensions and weight limits of a tractor-trailer or specialized truck. Consequently, their gantries and structural frames are typically more compact or use lighter materials to keep overall unit weight manageable.

Stationary CT suites, meanwhile, can accommodate larger, more robust gantries with minimal concerns about weight distribution or external chassis support.

Effect on Equipment Durability

- The constraints of fitting into a truck body can lead to slightly less rugged mechanical structures or smaller housings for internal components. In permanent rooms, more space is allocated for cooling systems, larger gantry frames, and extended electronics racks.

Shielding and Room Layout

Mobile Shielding

Mobile CT units typically have built-in lead shielding around the gantry and minimal shielding elsewhere (plus limited operator shielding partitions).

Fixed CT rooms are custom-built with extensive lead lining in walls and doors, ensuring that scattered or stray radiation is tightly contained.

Impact on Room Workflow

Because a mobile trailer or truck has finite space for patient positioning and staff operations, scanning can be more cramped, especially for staff who need to maneuver around limited corridors.

Power and Cooling Limitations

Power Supply

Voltage and Amperage Requirements

Many mobile CT scanners rely on 480V, 3-phase power but must also be designed to run from a generator if on-site power is unavailable. These power constraints can limit maximum outputs for the x-ray tube or the speed of certain hardware components.

Permanant scanners can tap into robust hospital electrical systems that accommodate higher power loads without compromise, enabling faster scanning modes or higher tube currents.

Cooling Efficiency

Mobile Climate Control

Mobile trailers use built-in HVAC systems that must handle varying outdoor temperatures. Cooling must be compact and efficient within the trailer’s limited space.

Fixed rooms often have dedicated, high-capacity air conditioning and advanced ventilation systems designed specifically to maintain optimal gantry and electronics temperatures.

Potential Thermal Constraints

Under heavy workloads, a mobile CT might temporarily limit scan throughput or automatically throttle x-ray tube usage to avoid overheating. Fixed systems, which benefit from robust cooling, can often handle higher patient volumes without similar interruptions.

To make sure you don't run into any power or cooling issues proper site prep is crucial.

Gantry Configuration and Detector Technology

High-Slice vs. Mid-Slice

Mobile Technology Tiers

Mobile scanners are commonly offered in mid-tier slice counts (e.g., 16-slice, 32-slice, 64-slice), which suit a broad range of clinical needs. While higher slice count mobile units exist (128-slice or above), they are less common and can be more expensive to operate and maintain.

Stationary scanners are frequently available in high-end configurations (128, 256, or even 320-slice), especially for specialized centers handling advanced cardiac or neurological imaging.

Detector Efficiency and Speed

Compact vs. Full-Sized Arrays

Some mobile units might use slightly smaller detector arrays or older-generation detector materials to keep weight and cost down.

A permanent suite might house the latest generation of wide detector arrays, enabling faster scans, greater coverage in a single rotation, and advanced applications (e.g., perfusion imaging).

Image Quality and Throughput

Tube Current and Rotation Speed

Hardware Constraints

Mobile scanners often run on lower maximum tube current or have slightly longer rotation times, especially if they’re older or less high-powered models. This can impact the speed of scanning or the clarity of images in challenging patient cases (e.g., obese patients, rapid sequence acquisitions).

Fixed suites can push the x-ray tube to higher outputs and faster rotations, supporting advanced protocols like triple-rule-out cardiac scans in under a second.

Advanced Imaging Applications

Cardiac CT, Perfusion, and Spectral Imaging

While some mobile units support advanced techniques like cardiac gating or dual-energy scanning,

many are configured for standard head, chest, abdomen, and pelvis exams.

Stationary high-end systems excel at specialized applications, offering spectral imaging or perfusion scans that require higher data acquisition rates and specialized reconstruction hardware.

Artifact Susceptibility

Motion and Vibration

Mobile units may be parked on uneven surfaces or experience vibrations, potentially introducing minor artifacts. Proper leveling and stabilization can mitigate this, but it’s a factor absent in permanent rooms designed for stability.

In stationary environments, scanners are installed on dedicated, vibration-isolated floors, minimizing mechanical interference.

Want more info on what type of image quality to expect from a Mobile CT scanner? Learn more HERE.

Workflow and Patient Experience

Patient Access

Limited Waiting/Prep Areas

In mobile CT trailers, pre-scan prep often happens in a small antechamber or shared waiting space, which can feel cramped.

In a fixed CT suite, hospitals can offer larger waiting rooms, sedation bays, and private changing areas for patient convenience.

Technologist Comfort

Operator Controls

Control consoles within mobile trailers are typically compact. While functional, they may not offer the multi-monitor layout or ergonomic space found in a conventional control room.

Stationary rooms may give technologists ample space for advanced post-processing stations, phone lines, and comfortable seating.

Service and Maintenance

On-the-Road Upkeep

Mobility Challenges

A CT unit in transit experiences more wear and tear, from vibrations and temperature fluctuations. Maintenance intervals may be more frequent, or the risk of damage from rough roads might be higher.

Stationary suites skip these transport challenges, allowing for stable upkeep.

Cost vs. Benefit

Financial Considerations

Rental/Lease Options

Mobile solutions often come as rentals or leases, which can be economical for short-term expansions or bridging intervals during renovation.

Permanent units demand high capital investments but may have lower per-scan costs over many years.

Hospital or Clinic Priorities

Flexibility vs. Capacity

A mobile CT is unmatched for flexible, on-demand coverage. However, if your patient volume is consistently high, a permanent, high-throughput system might yield better returns.

A

mobile CT scanner excels at delivering quick, flexible imaging capabilities—especially where expanding or building new CT suites is cost-prohibitive or infeasible. Yet, mobility brings certain

limitations: more modest scanner options, potential constraints on power and cooling, and the need to carefully level and maintain the trailer environment. For high-volume centers offering advanced studies or requiring maximum throughput, a

fixed CT suite often provides superior imaging power, layout customization, and patient comfort.

If you’re balancing these pros and cons, your choice depends on clinical demands, financial outlook, and logistical flexibility. For temporary coverage or satellite expansions, a mobile unit may be the perfect solution—so long as you prepare for its technical constraints. For the highest-tier imaging applications and long-term stability, a permanent system may still hold the edge.